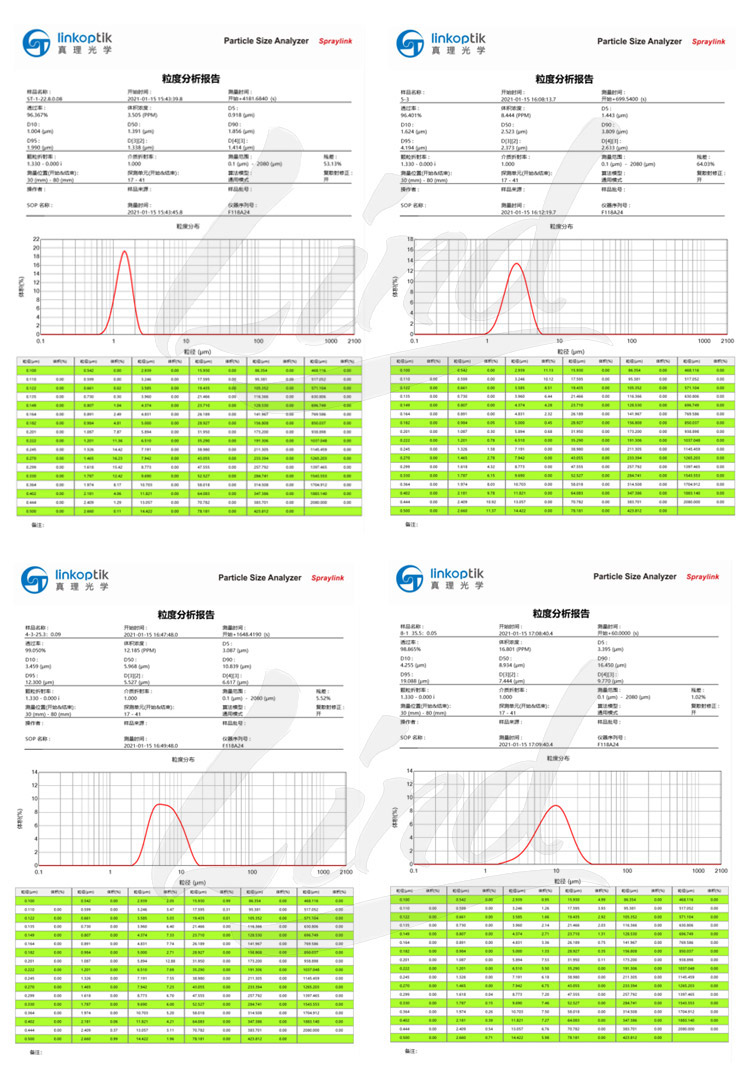

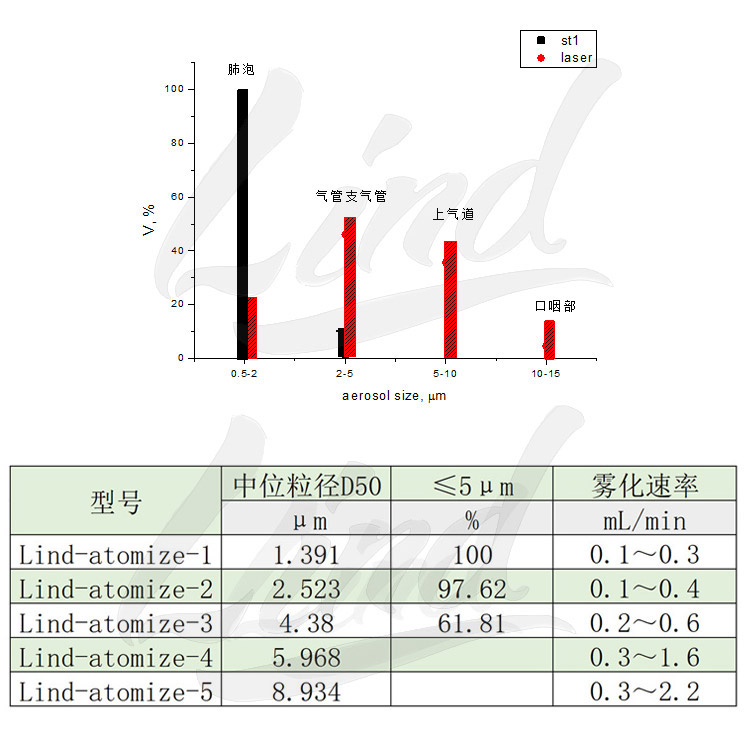

With the profound understanding of diseases such as emphysema, asthma, chronic obstructive pulmonary disease and cystic fibrosis, people have become more aware that pulmonary drug delivery is a targeted and non-invasive drug delivery system. Therefore, the development of non-invasive drug delivery technology will become a new technology hotspot in recent years. Pulmonary drug delivery is more and more popular because of its obvious advantages. Compared with other drug delivery methods, the lung has a larger absorption area, thin alveolar epidermis, and rich capillary network and other characteristics. It can avoid the first pass effect through the liver and directly deliver the drug to the local or systemic area, so it is convenient to use withfast effect. This novel approach to pulmonary drug delivery is likely to be one of the priorities of respiratory drug delivery formulations. The particle size distribution of the drug powder in the inhaled airflow is a key factor that affects the inhalation efficiency of DPI. It is generally believed that pharmaceutical powders with aerodynamic particle diameters ranging from 1 to 5 μm can be effectively absorbed. The results showed that when the particle size was larger than 10 μm, most of the particles were deposited in the upper respiratory tract. The drugs with particle size less than 0.5 μm were easily exhaled or adhered to the oral cavity before precipitation, while the vaporized particles with particle size of 0.5~ 5 μm could be deposited in the lower respiratory tract to the maximum extent.

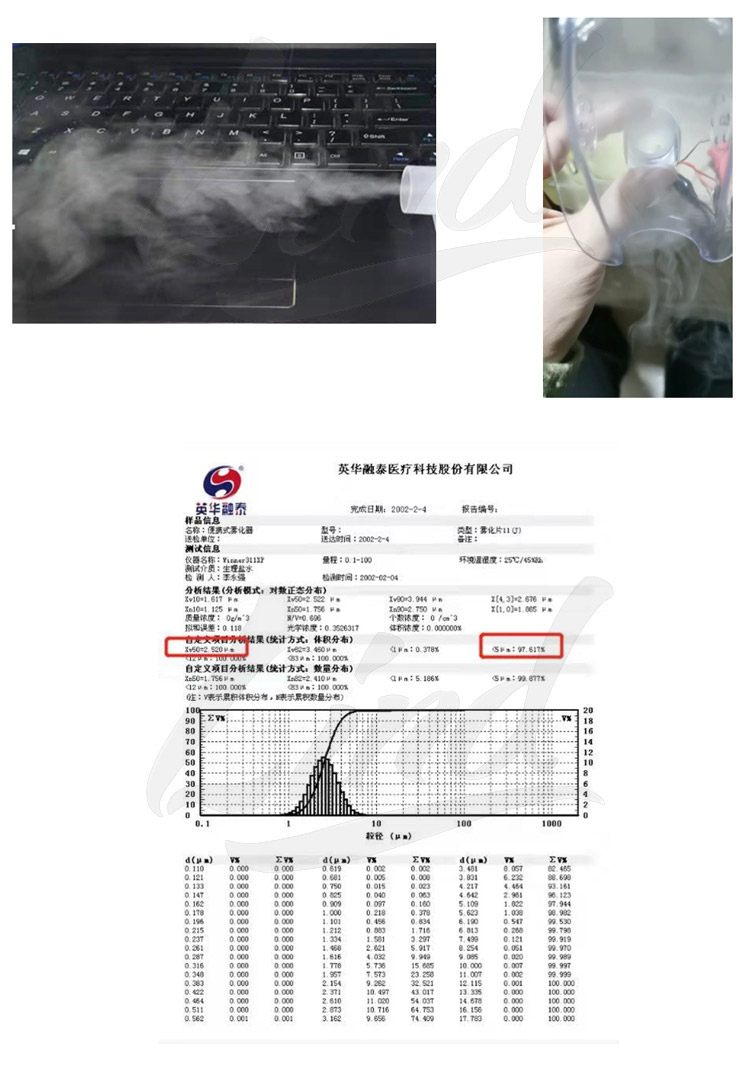

The main types of traditional sprayers are centrifugal, pressure and airflow. The atomizers used on these devices produce relatively large aerosol and have a wide particle size distribution due to their structural characteristics. At present, a new type of microplate atomizer has been developed, which uses piezoelectric drive to make fluid pass through a microplate with a diameter of 3-10 μm to form a spray. According to the vibration form of the microplate, the atomizer can be divided into Static Mesh Nebulizers and Vibrating Mesh Nebulizers; the static mesh nebulizers are produced by ultrasonic transducers. High-frequency vibration pushes the fluid to spray out of the static mesh into a mist.The pore shape of the microporous in the vibrating mesh nebulizer is a kind of structure with large top and small bottom, and the fluid contact with the microporous plate with high frequency vibration can form a microjet under the microporous plate. This vibrating mesh atomizer adopts the form of a thin piezoelectric ceramic sheet directly bonded with a microporous plate to form a piezoelectric ceramic atomizing sheet, which has good performance on atomization effect and lower power. The uniform pore size, regular pore shape and accurately controlled pore density of track etched pore membrane make it an ideal pore plate material for preparing atomized tablets for targeted therapy. The vibration micromesh atomizer prepared with it as the base material has narrow and uniform particle size distribution and little influence on the temperature of the liquid medicine during normal operation. Especially, it has advantageof good drug compatibility because the membrane material is nonmetallic material.