Research and Development Background of Lind membraneAnti-counterfeiting Technology

At the beginning of last century, the global volume of fake and shoddy goods was only $500,000, but by the beginning of this century, it had exceeded US $100 billion. Since 1990, the growth rate of global trade volume of counterfeit goods is 3.2 times that of global trade volume. The phenomenon of counterfeit and shoddy goods has become "the second largest public hazard in the world after drug trafficking".

In order to protect the interests of enterprises and consumers and ensure the healthy development of market economy, the country and enterprises spend a lot of manpower and financial resources on anti-counterfeiting every year. It is under this background that various anti-counterfeiting technologies have been derived.

From the initial laser code anti-counterfeiting, fluorescent ink anti-counterfeiting, temperature anti-counterfeiting, luminous anti-counterfeiting, digital anti-counterfeiting, to the research and development of nuclear energy anti-counterfeiting technology, they all have played a vital role in safeguarding national interests and protecting consumers' rights and interests.

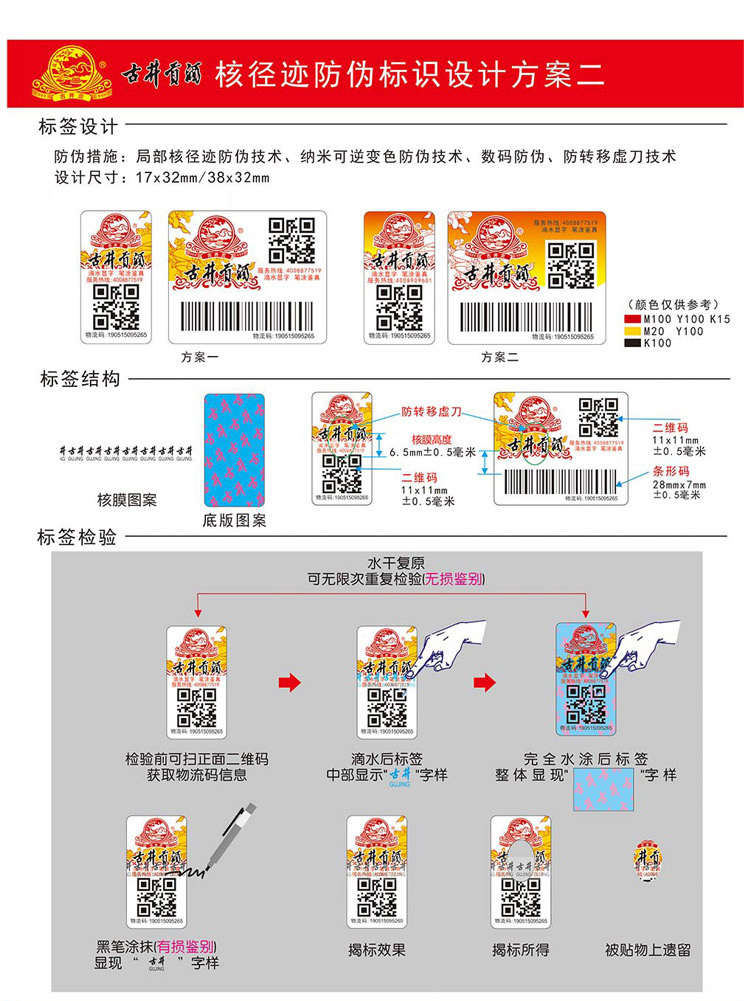

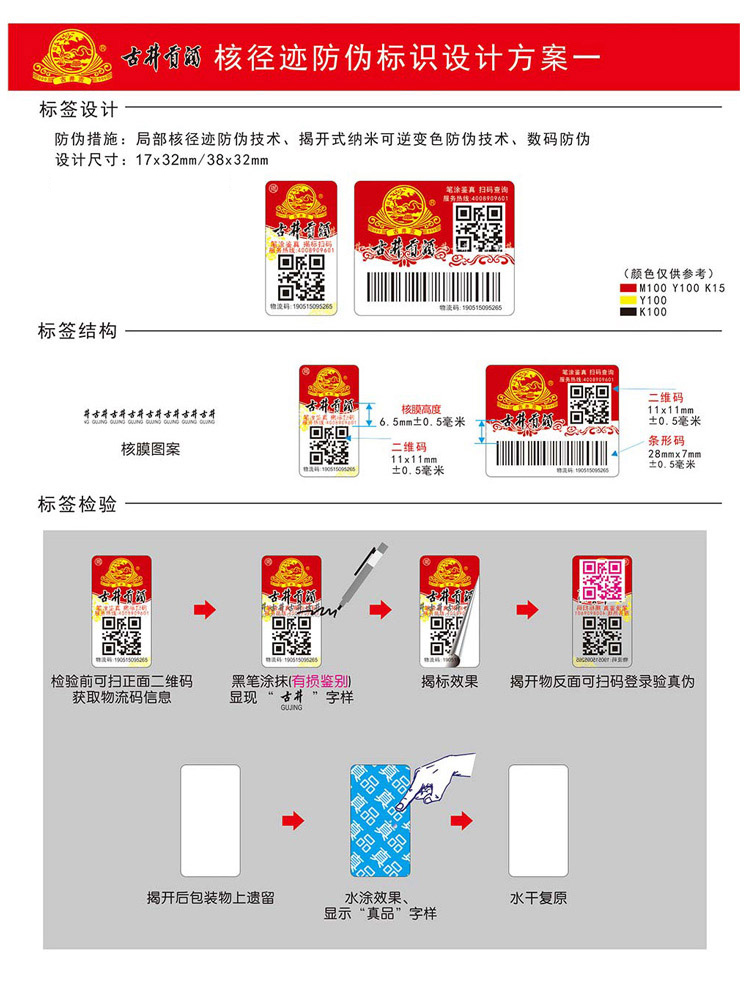

Introduction of Lind membrane Energy Anti-counterfeiting Technology

Nuclear track anti-counterfeiting technology is so called now as Lind membrane anti-counterfeiting technology, which is a scientific and technological achievement of the National 863 plan, China's original anti-counterfeiting technology and has obtained more than ten national patents. It is the only anti-counterfeiting technology listed in the National Key promotion program of scientific and technological achievements by the Ministry of Science and Technology.

Nuclear Track anti-counterfeiting technology products are made by high-energy particles through a special process to form a predetermined pattern with cylindrical micron-level through holes in plastic film. The density of micropores is 400 to 3 million per square centimeter. The micropores are randomly distributed on the plane. The pores have good air and water permeability. Then the film and the base material are combined through a special process, and then printed to make the anti-counterfeiting mark required according to the customer requirements.

In the anti-counterfeiting applications of many well-known brands, including the world's top 500 enterprises, for nearly two decades, none of them has been counterfeited, and its reliability has been widely recognized.

Characteristics of Anti-counterfeiting Technology

Monopoly of Production

The production process of nuclear track anti-counterfeiting materials uses special reactors and other important national nuclear facilities, which are expensive and subject to strong national supervision. It also requires the joint participation of multiple disciplines such as nuclear physics, chemistry, and electronics to complete. Therefore, it is highly monopolistic.

Inimitability

The pattern of the nuclear track anti-counterfeiting label has the characteristics of "microscopicallypassword-setting and macroscopically display", which makes the invisible multi-million-pixel collection "enlarge" into a visible macroscopic pattern. The micropore density, micropore inclination, aperture and their unique distribution rules of nuclear track anti-counterfeiting marks form a strict cryptographic signal, which is an obstacle that imitators cannot overcome. Under the microscope, it can be clearly identified whether it is processed by the nuclear facilityor not, and it can be proved that no other technology can be used to produce a similar anti-counterfeiting technology pattern.

Public Recognition

With colored liquid daub on the anti-counterfeiting mark, the invisible pattern or text in the anti-counterfeiting mark appears, showing the corresponding color.

Judicial Identification

Nuclear micropores in nuclear track anti-counterfeiting label have very strict micro scientific parameters, and strict password signals are formed through process control parameters, which are permanently stored in the labeling and become the scientific basis for expert identification and legal identification.

Recognition Methods

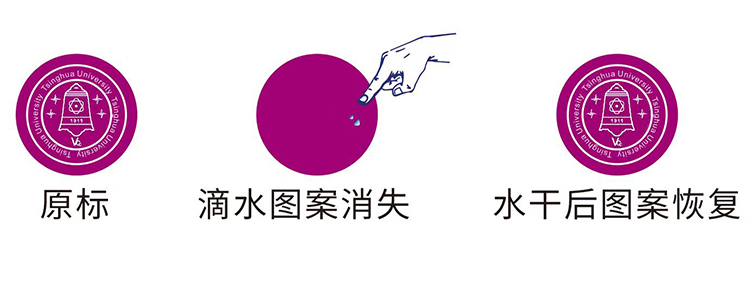

1. Identification Method of Dripping Disappearance

With a drop of water or any colorless liquid daub on the anti-counterfeiting label, the milky white pattern formed by the nuclear micropores on the film disappears immediately, presenting the color of the substrate. After the water dries, the pattern is restored, which is a reversible change and can be repeatedly identified.

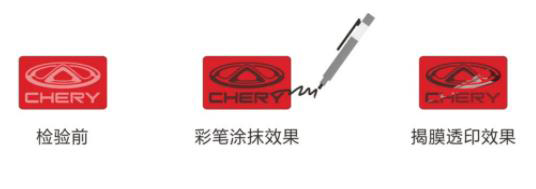

2. Identification Method of Pen Coating

Use colored pens, lipsticks, printing oil or other colored liquids to daub the anti-counterfeiting mark, and then wipe the mark dry, the invisible pattern or text in the anti-counterfeiting mark will appear and show the corresponding color.

应用品牌